Shop

Showing 25–36 of 55 results

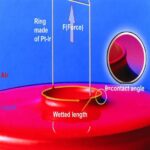

FORCE TENSIOMETER, K20

The versatile semi-automatic tensiometer for quality control

It is the specialist for quality control-everywhere that surfactants are used and for measuring surface and inter facial tension of liquids using the Wilhel my Plate or the Du Noüy Ring method. In addition, it is able to determine the density of liquids.

The motorized sample stage can be manually as well it is driven smoothly by an electric motor for quick measurement. It can be powered by rechargeable batteries, so it is suitable for flexible use as a portable stand-alone instrument.

It is available as the manual standard version K20S and the semi-automatic instrument K20.

TENSÍÍO

The new generation tensiometer for liquid and solid surfaces

Theoretically, building a tensiometer is simple: putting a moveable sample stage underneath a force measuring device. But developing the best-in-class tensiometer is something completely different. It takes more than just using an utterly precise force sensor (which we did) and the most sample positioning with the widest dynamic range (which we developed). It takes a change of perspective that focuses on the user and his task – you and your task. It takes the will to make your lab work as convenient, flexible, and time-saving as possible. We believe that Tensíío is that kind of instrument.

SPINNING DROP TENSIOMETER

The SDT Spinning Drop Tensiometer measures interfacial tension with a high degree of accuracy and a particularly wide range down to very low values. The SDT is the ideal solution for the quality control and development of emulsions and surfactants thanks to its enormous bandwidth, small sample volumes, and simple handling during preparation. The instrument is particularly well-suited for analyzing the interfacial behavior of mini- and microemulsions, e.g. for enhanced oil recovery (EOR) or the pharmaceutical and cosmetics branches.

BPT MOBILE

Immerse – click – read: Capture the surfactant concentration of your bath within seconds using surface tension (SFT) with the BPT Mobile Bubble Pressure Tensiometer. The quality inspector using it knows immediately if the bath is okay thanks to an ad-hoc evaluation. Moreover, for proactive adjustment of the bath, the BPT Mobile shows how the surfactant content decreases over time.

BUBBLE PRESSURE TENSIOMETER

The Bubble Pressure Tensiometer from KRUSS helps to characterize the surfactants efficiency as never before. This instrument is used to get information about wetting and drop formation in rapid processes.It measures dynamic surface tension with high accuracy.

BP100 measures the behavior of a surfactant over a wide speed range as part of a single, fully automatic measuring process. This enables you to find out how quickly a surfactant acts and when the required surface tension has been reached.BP100 is also suitable for checking the surfactant content of cleaning or galvanic baths. The dynamic surface tension responds particularly sensitively to changes in the surfactant content in the concentration range of such baths, thus enabling these changes to be reliably determined.

COLD FINGER CF 15

The PSL Coldfinger CF 15120 is equipped with up to 15 measuring places for multi-place testing. Combining multiple cold fingers in one heating bath facilitates screenings on wax inhibitors, e.g. simultaneous testing of different chemicals on a single sample or testing of different inhibitor concentrations with the same sample. The Cold Finger can be run with separate temperature control and stirring speed for each rack of 5 measuring places, thus reducing full test procedure for a single sample immanently. The dry bath allows a precise temperature control up to +120 °C / +248 °F.

DYNAMIC STABILITY LOOP

The Dynamic Stability Loop (DySL) by PSL Systemtechnik was designed to test long-term stability of umbilical chemicals in the lab at very stringent conditions. The DySL combines up to six loops for measurements of long-term changes of viscosity and tube blocking tendencies at pressurized conditions.

DYNAMIC FOAM ANALYZER

The DFA100 Dynamic Foam Analyzer measures the foamability of liquids and the stability of quickly decaying or long lasting foam based on reproducible foaming and height detection. With optional modules operating in parallel, it also measures the liquid content or analyzes the foam structure with regard to bubble size and distribution. The DFA100 supports you in optimizing foam-forming products or helps you to avoid unwanted foam formation.

FOAM TESTER FOA

The Foam Tester FOA enables the investigation of foams with regard to foam production, stability and foam decomposition.

Based on the ASTM D892 the Foam Tester FOA extends the measuring possibilities to increased pressure ranges with only insignificant changes in design. Even aqueous liquids can now be tested under pressure for their foaming behaviour at elevated, previously inaccessible temperatures of more than +100 °C.

Surface Tension Instruments

Surface Tension Instruments  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants  Material Testing Service

Material Testing Service  Emulsion & Suspension Analysis

Emulsion & Suspension Analysis