Contact Angle Measurement Systems

Showing all 9 results

AYRÍÍS

Getting rid of any user intervention and result interpretation whatsoever, our Ayríís uses groundbreaking technology for perfectly reliable QC checks of wettability. With just one click and in seconds, the 3D Contact Angle of water is measured and auto-validated with a simple passed/failed message using preset quality limits. The highly advanced 3D drop projection technique of Ayríís provides for automatic self-checking of consistency and plausibility of each result. As a mobile, stand-alone instrument with easy-to-exchange rechargeable batteries and prefilled cartridges, Ayríís is prepared to operate 24/7 on your production site.

MOBILE SURFACE ANALYZER (MSA)

MSA measures surface free energy with two liquids, fully automatically and mobile using our new “One-Click SFE” method. The MSA doses two parallel drops with one click, followed by the direct analysis of the contact angles and the derived results of the surface free energy. All steps are automated and happen within a second.

The precise measurement and scientific evaluation are performed with a single button click. Thus, measurement errors due to incorrect operation are virtually ruled out.

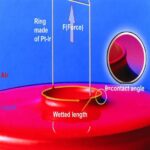

DSA25 CONTACT ANGLE METER

The entry level instrument which is an easy-to-use and reliable for measuring contact angle, Surface Free energy and Surface & Interfacial Tension measurement by Pendent drop method.

The trend to water-based bonding, coating and printing on plastics has made solving wetting problems an important challange, With the DSA25, KRUSS covers the increasing demand for rapid wetting tests.

DSA25 Series configuration

- DSA25 B: Basic configuration.

- DSA25 S: Standard configuration.

- DSA25 E: Expert configuration.

DSA 30 DROP SHAPE ANALYSIS SYSTEM

DSA30 is a robust instrument which can be used flexibly for the precise measurement of contact angle and surface free energy. With high-quality components and various automation options, the DSA30 analyses wetting and adhesion on solid surfaces. Fast measurements and simple operation make the instrument a valuable part of your routine quality control.

DSA30 Series Configuration:

- DSA30 B: Basic Configuration.

- DSA30 S: Standard Configuration.

- DSA30 E: Expert Configuration.

DSA100 DROP SHAPE ANALYSIS SYSTEM

Drop Shape Analyzer (DSA100) is a high-quality system solution for almost all tasks in the analysis of wetting and adhesion on solid surfaces. From the basic unit for precise measurement of the contact angle to the fully automatic expert instrument for serial measurement of surface free energy, This is the right instrument for your special requirements.

DSA100 Series configuration.

- DSA100 B: Basic configuration.

- DSA100 S: Standard configuration

- DSA 100 E: Expert configuration.

DSAHP DROP SHAPE ANALYSIS SYSTEM – HIGH PRESSURE HIGH TEMPERATURE

The Drop Shape Analyzer – DSA100HP is our high-quality solution for the precision measurement of contact angle as well as surface and interfacial tension under pressures up to 1750 bar. In order to carry out the measurement, the DSA100HP’s high-resolution camera records video images of dosed drops through the pressure cell’s viewing windows and these are then evaluated in real time.

DSA100 Series configuration.

- DSA100HP40 : Maximum Pressure – 40 bar (580 psi)

- DSA100HP690 : Maximum Pressure – 690 bar (10 000 psi)

- DSA100HP1750 : Maximum Pressure – 1750 bar (25 000 psi)

TVA100 TOP VIEW ANALYZER

It is the only instrument in the world to use the top-view reflection method for measuring the contact angle of a liquid on a solid from above. TVA100 determines the contact angle using the radius of curvature of the upper surface of the drop. The innovative measuring method is particularly suitable for measurements in depressions and on concave surfaces where drops cannot be analyzed using the conventional side view.

The measuring head is available as a module for the well-proven KRÜSS DSA100, DSA30 and Easy Drop instruments and also as an independent portal system for contact-free measurements on large samples.

Surface Tension Instruments

Surface Tension Instruments  Particle Characterization

Particle Characterization  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants  News

News  New Project

New Project  Offers

Offers  Seminars/Exhibitions

Seminars/Exhibitions  Careers

Careers  Testimonial

Testimonial  Blog

Blog

Laboratory Baths and Circulators

Laboratory Baths and Circulators