Material Testing Instruments

Showing all 2 results

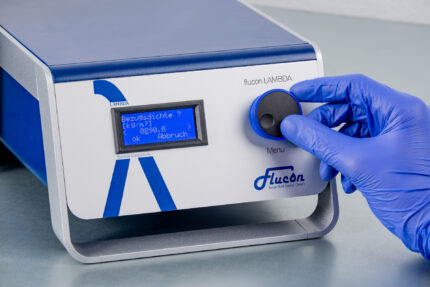

LAMBDA Thermal Conductivity Meter

LAMBDA is a compact, operator-friendly transient hot wire instrument that facilitates a fast determination of the thermal conductivity, thermal diffusivity and specific heat capacity in a wide temperature and pressure range by means of the transient hot wire (THW) method, according to ASTM D7896-19.

This highly accurate athermal calorimeter is suited for fluid analysis in the laboratory as well as in the field, including the measurement of thermal conductivity of nanoparticle dispersions/nano fluids.

Our LAMBDA Thermal Conductivity Meter can be operated either in stand-alone mode or with the intuitive software (incl.) on your WINDOWS computer via RS-232/USB.

highly accurate thermal conductivity meter for laboratory use

wide measuring range (10 - 2000 mW/(m*K))

wide temperature range (-50°C to 300°C)

fast, instationary resistance measurement by means of the hot wire method

conforms to ASTM D7896-19

robust stainless steel sensor

no unwanted influence of convection

suitable for any type of fluid, powder or gel

requires only small sample volumes (approx. 40 ml)

high accuracy and repeatability (+/- 1 %)

thermal conductivity (λ), thermal diffusivity (aT), specific heat capacity (cp) and temperature are displayed

QVis 01/o Process Viscometer

Our QVis 01/o inline viscosimeter automates your viscosity monitoring and generates measuring results that are reproducible and documentable.

Banish flow cups and keep track of your fluid viscosity at all times!

Surface Tension Instruments

Surface Tension Instruments  Particle Characterization

Particle Characterization  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants  News

News  New Project

New Project  Offers

Offers  Seminars/Exhibitions

Seminars/Exhibitions  Careers

Careers  Testimonial

Testimonial  Blog

Blog

Laboratory Baths and Circulators

Laboratory Baths and Circulators