Petroleum Testing Instruments

Showing 1–12 of 19 results

Cold Finger cCF6

The Coaxial-Shear Cold Finger cCF6 is a high-performance laboratory device developed to analyze wax deposits and evaluate the efficiency of wax and paraffin inhibitors under realistic shear conditions. It features six rotating cold fingers housed in a temperature-controlled water bath, allowing for simultaneous testing and reproducible results.

A pneumatic lift system simplifies handling by enabling safe and quick access to samples and measuring sleeves—enhancing both safety and efficiency during operation.

With its compact, modular design, the cCF6 delivers exceptional ease of use, accurate measurement, and high flexibility. Its ability to control and replicate shear conditions across all measuring stations makes it ideal for advanced research and quality control in the petroleum and crude oil industries.

Cold Finger CF6

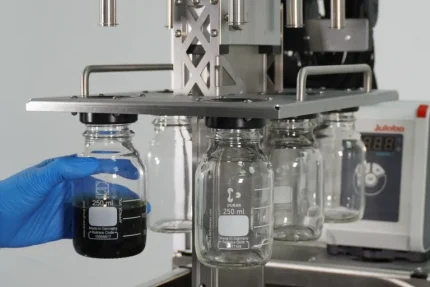

The Multi-Place Cold Finger CF6 is a laboratory instrument designed to analyze wax deposits and evaluate the effectiveness of wax and paraffin inhibitors. It features six measuring stations arranged in a conventional water bath, enabling simultaneous testing and significantly reduced measuring times.

Expanding the trusted PSL Cold Finger product family, the CF6 stands out with its compact, space-saving design and an integrated sample lift. This ensures precise positioning of the cold fingers in the sample bottles, offering users enhanced convenience, improved safety, and more accurate results.

Tailored for laboratories with low to medium sample volumes, the CF6 is an ideal entry-level solution for cold finger measurements in crude oil and petroleum product testing.

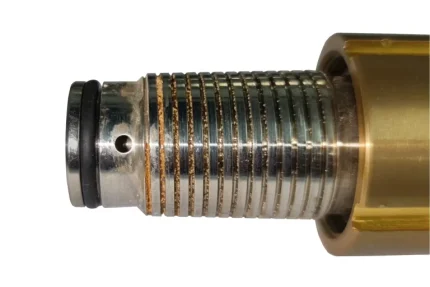

Cold Finger mCF2

The Mobile Cold Finger mCF2 is a compact, transportable device designed to test wax and paraffin deposits and assess the efficiency of inhibitors in crude oils. With two measuring stations and a minimal footprint, it is ideal for low-throughput laboratory testing or on-site use in the field, independent of a traditional lab setup.

For over a decade, PSL has set the standard in Cold Finger technology—pioneering methods that allow for multiple measurement intervals per sample and delivering highly precise results with weight-adjusted sleeves.

Now, the proven precision of PSL Cold Finger instruments is available in a mobile format. The mCF2 maintains the same level of comfort, accuracy, and reliability as its larger counterparts, making it the new standard for professionals who need mobility without compromising performance.

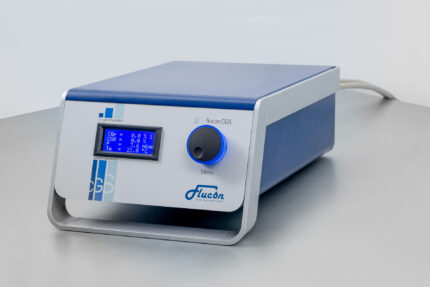

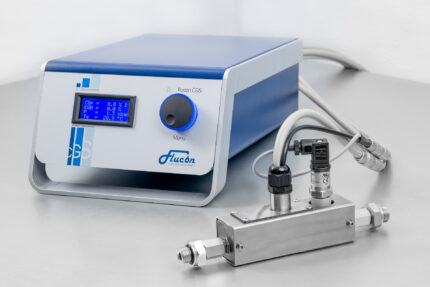

Mobile Differential Scale Loop (mDSL)

Faster, Easier, and More Flexible Inspection of Scale Deposits in Pipelines

The mobile Differential Scale Loop (mDSL) is an advanced tube-blocking system designed for on-site analysis of crystalline deposits from aqueous solutions—such as salts, carbonates, sulfates, iron compounds, sugars, and geothermal fluids. No longer confined to the laboratory, the mDSL offers the flexibility to conduct tests directly in the field or at the customer’s location.

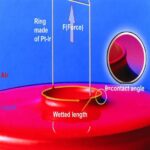

Surface Tension Instruments

Surface Tension Instruments  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants  Material Testing Service

Material Testing Service  Emulsion & Suspension Analysis

Emulsion & Suspension Analysis