| Features |

Operating pressure up to 2000 bars (7000 bars for the hydrothermal synthesis autoclave) |

|---|

Batch reactors with bolted yoke or clamp and screw

For applications requiring temperatures above 250°, or pressures above 300 bar, the autoclave type design with plug and screwed head is no longer suitable, either because the force exerted by the pressure is not compatible with the strength of a thread, or because the temperature imposes low compressible seals which therefore require a precise torque.

In this case, TOP Industrie designs and manufactures autoclaves with bolted heads, with a sealing ensured by Kalrez, PTFE or metal seals. In the same way as for the quick-closing autoclaves, TOP Industrie realizes an almost infinite range of diameter/height torques allowing the user to choose the volume and the H/D ratio best adapted to his experiments.

The whole range of accessories and peripherals useful to the world of research and university or industrial experimentation is available.

- Magnetically coupled stirrers,

- Heating by heating collar, oven or double jacket,

- Cooling at the end of the cycle, or in case of exothermicity by Vortex or coil type circulation.

- Pressurization and regulation, transfer and management of fluids, liquids, gases, powder.

- Injection and sampling of gases and liquids.

- Filters, separators, catalyst baskets.

- Mounting on aluminium profile frame or with pneumatic or hydraulic lift.

- Complete control of the whole unit by touch screen or LabVIEW development on PC.

- Pressure measurement, temperature control, stirring speed control, flow measurement, gas consumption…

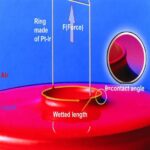

Surface Tension Instruments

Surface Tension Instruments  Particle Characterization

Particle Characterization  Foam Analyzers

Foam Analyzers  High Pressure Reactors and Pilot Plants

High Pressure Reactors and Pilot Plants  News

News  New Project

New Project  Offers

Offers  Seminars/Exhibitions

Seminars/Exhibitions  Careers

Careers  Testimonial

Testimonial  Blog

Blog

Laboratory Baths and Circulators

Laboratory Baths and Circulators